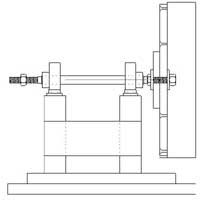

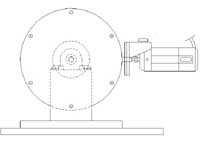

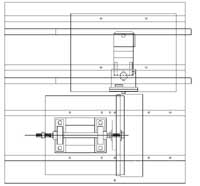

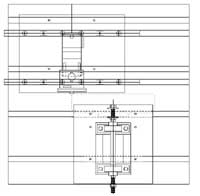

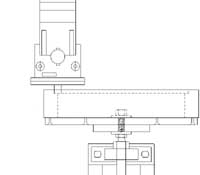

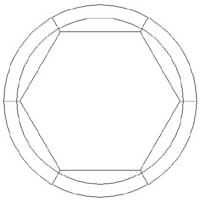

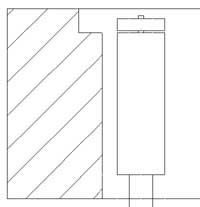

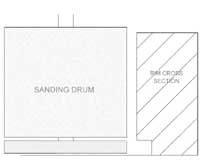

I have created three different incarnations of this idea. They all have the same basic concept: a router mounted on a moving base that cuts the rim as it is turned on a spindle. My first was very simple. The one shown here was my most ambitious and includes accommodations for truing the bottom edge and adding inlay strips at the joints of block rims. I have put this articletogether hastily for the benefit of a seeker on a Yahoo group. I'll try to add details later.

December 16, 2003